Published on 21 January, 2026

Changing the engine oil in a diesel generator is not complicated, but it has a major impact on the generator’s lifespan and reliability. Doing this simple task properly can significantly reduce metal wear, keep the engine clean inside and help maintain stable power output. For users in commercial buildings, construction sites or homes that rely on standby generators, delaying oil changes or using the wrong oil will greatly increase the risk of breakdowns. The following guide explains the correct diesel generator engine oil change method, recommended intervals and key points for choosing the right oil, so you can complete this essential maintenance with minimal time and effort.

Why change generator oil regularly?

Engine oil in a diesel generator does more than just lubricate moving parts. It also helps carry away heat and contaminants generated during operation. Over time, the oil oxidises and degrades, and its viscosity drops, reducing its protective performance and causing components to wear out faster. Regular oil changes keep the inside of the engine properly lubricated, reduce metal-to-metal contact and help prevent serious damage such as scoring of cylinder walls or even engine seizure.

Can neglecting oil changes destroy the engine?

If the engine oil is not changed at the recommended intervals, it will gradually turn very dark and thin, and its lubricating ability will drop sharply. It can no longer form a strong protective oil film between internal moving parts, directly accelerating the wear of key components such as crankshaft bearings, camshaft and piston rings. At the same time, engine cleanliness will deteriorate as sludge and metal particles build up. These deposits can block narrow oil passages, disrupt oil circulation and lead to local lubrication failure, which in turn can cause severe overheating or even catastrophic engine failure. In the worst case, the engine may require a major overhaul or complete replacement, and the repair cost can easily exceed the price difference of simply following a regular maintenance schedule.

Engine oil change steps

The steps below apply to most small to medium-sized diesel generators, but actual procedures should always follow the manufacturer’s manual.

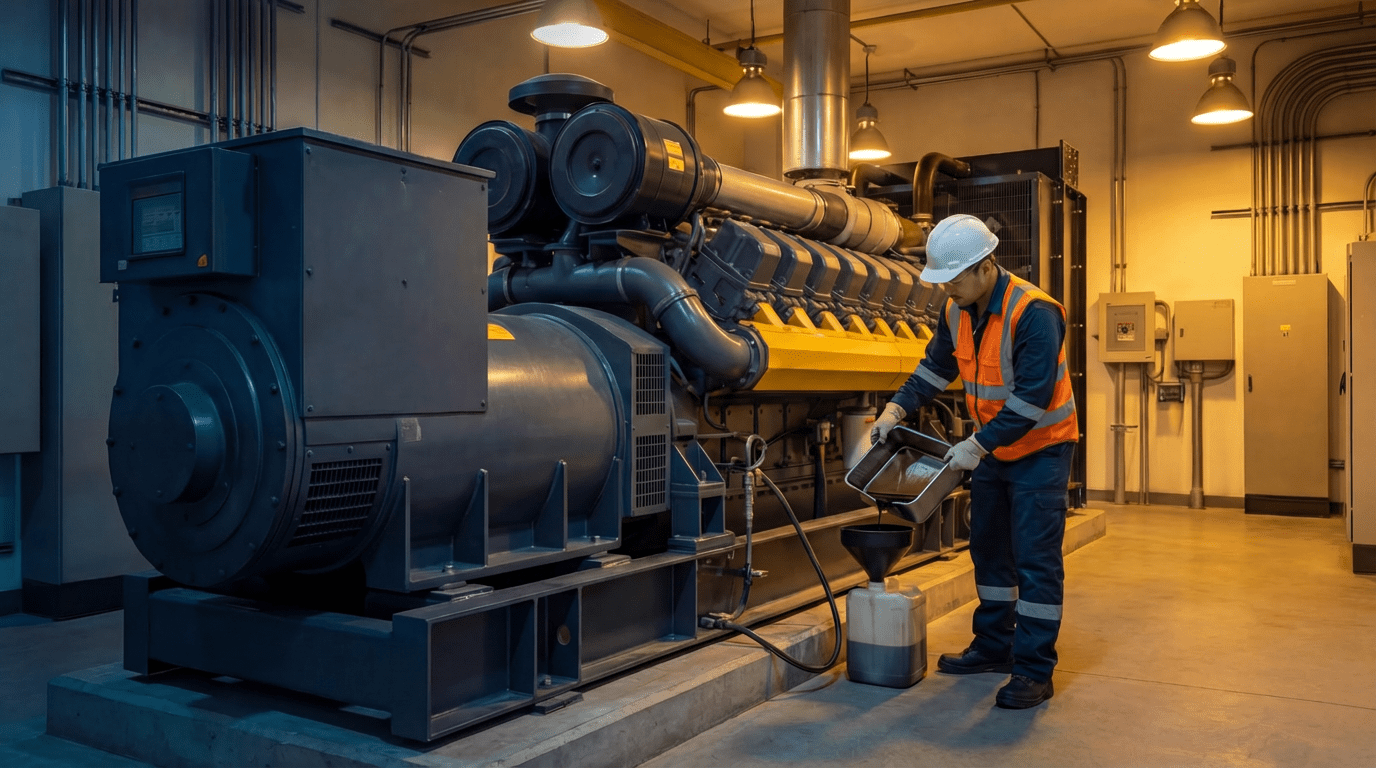

Step 1: Run the diesel generator for a few minutes, then shut it down. This slightly warms the oil and helps the old oil drain out more completely during the oil change.

Step 2: Switch off the main power supply and make sure the generator cannot start automatically (for example, turn off any auto-start function), then remove the drain plug at the bottom of the engine. Place a suitable container underneath to catch the used oil and remove the oil filter element. Once all the oil has completely drained out, refit and tighten the drain plug, then reinstall the oil filter element.

Step 3: Open the oil filler cap and, using a funnel, pour in the specified grade and quantity of new oil. Check the dipstick in stages, making sure the oil level stays between the minimum and maximum marks.

Step 4: Refit the oil filler cap and reconnect the power. Start the generator and let it run for about 1 minute, then shut it down and check the oil level again, as well as the area around the filter and drain plug for any leaks. Once everything is confirmed, the oil change is complete.

Common engine oil change mistakes

The following practices are prevalent but can seriously reduce the protective effect of the oil and shorten generator life:

– Relying only on visual inspection of oil colour and continuously delaying oil changes.

– Using oil that does not meet the required specification.

– Filling too much or too little oil.

– Only changing the oil, but not replacing the oil filter each time.

These mistakes increase the risk of carbon deposits, abnormal wear and blocked oil passages, which will shorten the service life of the generator.

How often should you change diesel generator oil?

Taking Cummins generator sets as an example, under normal operating conditions, a new generator or an engine that has just undergone major repairs should have its first oil change after the initial 20–50 operating hours, in order to remove metal particles produced during the running-in period. After that, a typical reference interval is every 250 operating hours or every 6 months, whichever comes first. For smaller portable generators, the interval is usually every 50–100 operating hours or every 6 months. As different brands and models may have different recommendations, always refer to the manufacturer’s manual as the most accurate guideline. In addition to operating hours, our technicians assess the condition of the generator and engine oil after each maintenance inspection to determine whether an oil change is necessary.

How to tell when it is time to change the oil?

Besides tracking operating hours, the actual condition of the generator is also an important indicator. If you notice any of the symptoms below, you should arrange an inspection and oil change immediately, even if you have not yet reached the recommended interval.

Check oil colour, consistency and smell

Using the dipstick to inspect the condition of the engine oil is the most straightforward method. If the oil is extremely dark, significantly thinner than normal or has a strong burnt smell, this indicates that the oil has severely degraded. If you can see obvious metallic particles or debris suspended in the oil, it usually means that internal engine components may be experiencing abnormal wear.

Watch for abnormal noise, high temperature and low oil-pressure warnings

If the engine becomes unusually noisy during operation, runs at persistently higher temperatures, or the oil-pressure warning light on the control panel comes on, these are warning signs of insufficient oil, low oil pressure or inadequate lubrication. In such cases, the oil may already have lost its protective properties and the issue must be dealt with immediately to prevent major engine damage.

Allow for high-load or harsh operating conditions

If the generator operates for long periods at high loads, in ambient temperatures above around 35°C or in dusty environments, the oil-change interval should be shortened accordingly. As a general guideline, it is advisable to check the oil condition every 150–200 hours under such conditions. In addition, even if a generator is only used as a standby unit and runs for very few hours each year, it is still recommended to change the oil at least once a year, because oil will naturally oxidise and lose its lubricating performance over time.

How to choose the right engine oil?

The key factors when selecting engine oil for a diesel generator are specification approvals and viscosity. Common approved specifications include heavy-duty diesel engine oils recognised by the American Petroleum Institute (API), such as CH-4 and CI-4, which are designed for turbocharged and high-load diesel engines used in generators, trucks and construction machinery.

If you focus on viscosity, 15W-40 is one of the most popular choices. It provides strong protection at high operating temperatures while still offering reliable cold-start performance. In regions with extremely low ambient temperatures, you can follow the manufacturer’s recommendations and choose grades such as 10W-30. In all cases, the actual choice should follow the equipment manufacturer’s manual.

Keeping your generator running reliably

To keep a diesel generator running reliably over the long term, quality equipment and professional maintenance are both essential. Using a reputable global brand such as Cummins®, together with the correct grade of engine oil and regular oil changes, helps prevent carbon build-up and wear, and reduces the risk of performance loss or unexpected failures due to lubrication problems. We offer not only generator rental and purchase services, but also comprehensive maintenance guidelines and support. You are welcome to contact us for the generator solution that best suits your needs and tailored maintenance recommendations.