Published on 31 October, 2025

A reliable electricity supply is indispensable across all industries. When problems arise with the mains supply, or power is insufficient, a diesel generator serves as an emergency or even primary source of electricity. This is especially true for construction sites, large-scale events or critical facilities such as data centres, where dependable power provision has a direct impact on daily operations. This article outlines the principles, uses and advantages of diesel generators, and explains the factors influencing their efficiency and fuel consumption.

Principle of Operation

The central feature of a diesel generator lies in its effective conversion of the energy produced by diesel combustion into usable electricity. The operation takes place in two key stages:

Stage One: Diesel Engine Produces Mechanical Power

The principle behind a diesel generator is similar to that of an internal combustion engine found in vehicles. Its core is a diesel engine which generates mechanical energy through four repeating processes: Intake, Compression, Combustion and Exhaust.

1. Intake: The cylinder intake valve opens to admit fresh air into the engine.

2. Compression: The piston moves upwards, compressing the air within the cylinder and raising its temperature significantly.

3. Combustion and Expansion: At this high temperature and pressure, atomised diesel is injected into the cylinder, where it ignites spontaneously, causing a forceful explosion that drives the piston.

4. Exhaust: The piston rises again to discharge the combustion gases.

These processes repeat continuously, with the piston’s motion driving the crankshaft to rotate at a speed. This produces the steady mechanical energy required by the generator.

Stage Two: Conversion to Electricity

The mechanical energy generated by the engine is transferred to an alternator. The principle of electromagnetic induction is used: the engine rotates the internal rotor (a magnet) within a stationary set of windings (the stator), generating an electric current. This current is stabilised and regulated by a controller, ensuring a stable supply suitable for daily use.

Efficiency and Fuel Consumption

Two key indicators for evaluating a diesel generator are its efficiency and fuel consumption. How can one achieve maximum efficiency? How does one properly calculate fuel usage to keep operational costs under control? The following explains these issues:

Efficiency of Diesel Generators

Efficiency refers to the proportion of diesel’s chemical energy converted into electrical energy. Typically, diesel generators achieve a conversion rate of about 30% to 40%, depending on the model and load—It is more efficient than other types of power generation equipment (such as gasoline generators). Operating at consistently low or excessive loads can result in incomplete combustion of fuel, reducing efficiency and possibly causing damage to generator components.

Calculating Fuel Consumption

Many factors affect a generator’s fuel consumption—including unit output, load factor, engine technology and operational conditions. A commonly used formula is:

Fuel consumption (litres per hour) ≈ Power (kW) × Load factor (%) × Fuel consumption rate (g/kWh) ÷ 1000 ÷ 0.84 (fuel density)

For example, a 100 kW generator operating at 75% load with a specific fuel consumption of 220g/kWh would consume roughly:

100 kW × 75% × 220g/kWh ÷ 1000 ÷ 0.84 ≈ 19.6 litres per hour.

Larger generator sets generally achieve superior efficiency when operating at their optimum load. Selecting a generator of suitable output to meet practical needs is vital to controlling costs.

Main Advantages

Despite alternatives such as natural gas and solar power, diesel generators continue to be chosen in many sectors for the following reasons:

- High reliability: Diesel generators can start rapidly and reach their rated capacity within seconds, providing an immediate emergency supply should the mains fail.

- Greater fuel efficiency: Diesel has a higher energy density than petrol, providing more electricity per litre and lowering long-term fuel costs.

- Durability and longevity: Diesel engines are robust, operate at lower speeds and experience less wear, so they typically outlast petrol engines when maintained correctly.

- Relatively straightforward maintenance: Compared to natural gas systems, diesel generators are simpler to maintain and repair, and the necessary expertise is widely available.

- Enhanced safety: Diesel has a higher flash point and is less volatile than petrol, making it safer to store and handle.

Two Principal Applications

In Hong Kong, diesel generators have broad applications as both standby supplies and main power sources:

Outdoor Power

Diesel generators provide dependable electricity for outdoor concerts, major events, temporary exhibitions, or construction sites not connected to the grid, enabling the continued use of equipment and preventing disruptions.

Emergency Back-up Power

In residential and commercial buildings, diesel generators are often installed as an emergency measure to keep fire safety systems, water supplies and other essential functions operational during power outages. Facilities where no interruption to power is tolerable—such as hospitals, data centres and telecommunications stations—rely on standby diesel generators for continuous protection.

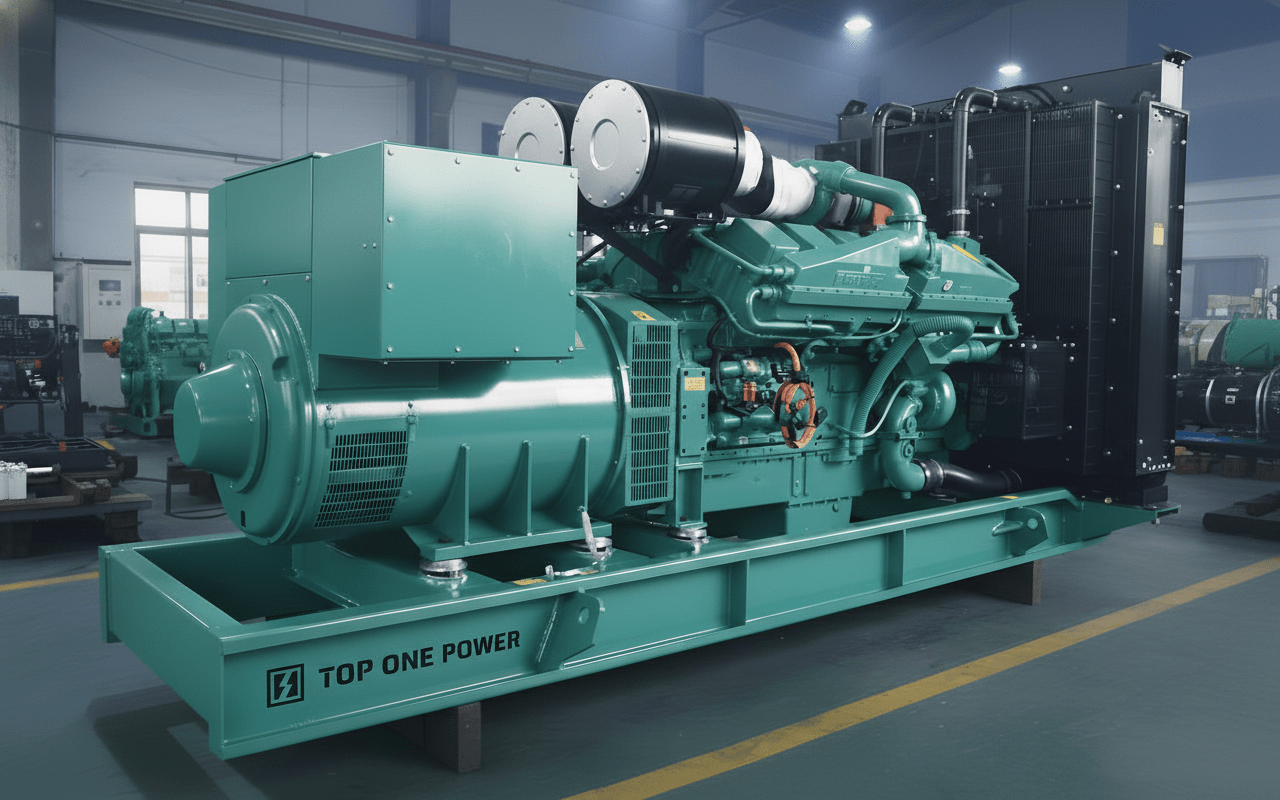

Reliable Cummins Diesel Generator Series

Given the efficiency and advantages diesel generators provide for both primary and back-up supply, it is important to select machinery that is reliable and established. We offer a comprehensive range of generators by Cummins®, a globally respected manufacturer with nearly a century of experience in engine design. Cummins generators are renowned for high efficiency, durability and endurance. Each unit is thoroughly tested before sale, and after-sales support is available to ensure safety and reliability. If your business requires a dependable diesel generator, please contact us for hire or purchase.