Published on 19 December, 2025

Diesel generators are the core equipment in backup or primary power systems. When the unit experiences operational abnormalities, such as insufficient output voltage from the diesel generator, it can affect the operation of critical equipment. To ensure a stable power supply, operators need to understand the causes of diesel generator failures and the corresponding solutions. This article will analyse several common failure symptoms and causes, while breaking down the average lifespan of generators, helping you gain better direction in operation and maintenance.

Common Diesel Generator Failures and Cause Analysis

Diesel generators are widely used as primary or backup power sources in hospitals, factories, residential buildings, and data centers. Once a unit fails, it can prevent connected devices from functioning normally. Below are common diesel generator failure scenarios and potential causes to help you initially identify the root of the problem:

| Failure Symptom | Potential Causes |

| Unable to start or difficult to start | Fuel supply interruption, low battery voltage, starter motor failure, engine damage, etc. |

| Shutdown during operation or abnormal output | Clogged fuel filter, incomplete diesel combustion, leaks in oil or water circuits, cooling system abnormalities, low oil pressure, overload operation, etc. |

| Unable to stop after starting | Solenoid valve stuck, control coil burned out, relay adhesion, abnormal ECU signals, etc. |

| Unstable output voltage or frequency | Governor failure, AVR failure, coil short circuit, unstable engine speed |

| Abnormal AC voltage output | Unstable engine speed, damaged AVR, stator winding open circuit, worn carbon brushes, etc. |

| Abnormal noise or vibration | Worn parts, loose fixing bolts, damaged bearings |

| Abnormal exhaust smoke | Black smoke is often due to excess fuel or clogged filters; white smoke is due to cold engine load or burned cylinder gasket; gray-white or blue smoke is often related to oil burning. |

Since there are many causes of diesel generator failures, having basic knowledge can improve maintenance efficiency. Additionally, if the generator is supported by a professional after-sales service and technical team, issues can be resolved more quickly, significantly reducing downtime and minimizing impact on equipment operation.

What to Do If Diesel Generator Voltage Is Insufficient?

During operation, if the measured output voltage is below the rated value (The rated voltage is the normal output set during machine design, such as three-phase 400V or 380V), it indicates low diesel generator voltage, which requires immediate resolution. Common causes include:

- AVR failure or incorrect settings are preventing the generator from providing sufficient voltage.

- Open circuit, short circuit, or insufficient current in the excitation coil responsible for generating the magnetic field, failing to maintain the field needed to induce the rated voltage.

- Loose or oxidized connection points in the diesel generator, causing a voltage drop and resulting in low

- Poor contact or excessive wear on carbon brushes and slip rings, affecting current transmission.

- Sudden connection of large loads with insufficient response performance, causing a temporary significant voltage drop.

Solutions

First, inspect, adjust, or replace the AVR to ensure the excitation system operates normally. Next, thoroughly check all connection terminals to rule out voltage drop issues caused by looseness or oxidation, and clean or replace worn carbon brushes and slip rings. If the temporary voltage drop is due to sudden large loads, improve the sequence of load startup, and confirm the sensitivity of the diesel engine governor to ensure the unit can quickly restore stable voltage and frequency.

How Long Is the Average Lifespan of a Diesel Generator?

Generally, well-designed and properly maintained medium to large industrial diesel generators have an average lifespan of over 8,000 hours, with some reaching 30,000 hours or even 50,000 hours. This means the unit can typically last 15 to 25 years. The actual lifespan depends on the generator model, size, and usage intensity, and can be further extended with proper maintenance and suitable operating environments.

Factors Affecting Diesel Generator Lifespan

Factors influencing diesel generator lifespan include:

- Daily operating hours and load conditions: Long-term high-load operation accelerates component wear and shortens lifespan.

- Environmental conditions: Harsh environments like high temperature, high humidity, dust, or corrosive gases accelerate part aging.

- Maintenance frequency and consumable replacement: Timely replacement of engine oil, fuel filters, coolant, and air filters ensures normal operation.

- Unit quality and manufacturing standards: Brand and design determine basic durability and performance stability.

- Operating habits: Including correct startup and shutdown procedures, avoiding frequent premature power cuts or excessive operation.

- Fuel quality and usage: Using poor-quality fuel can clog the injection system and cause component damage.

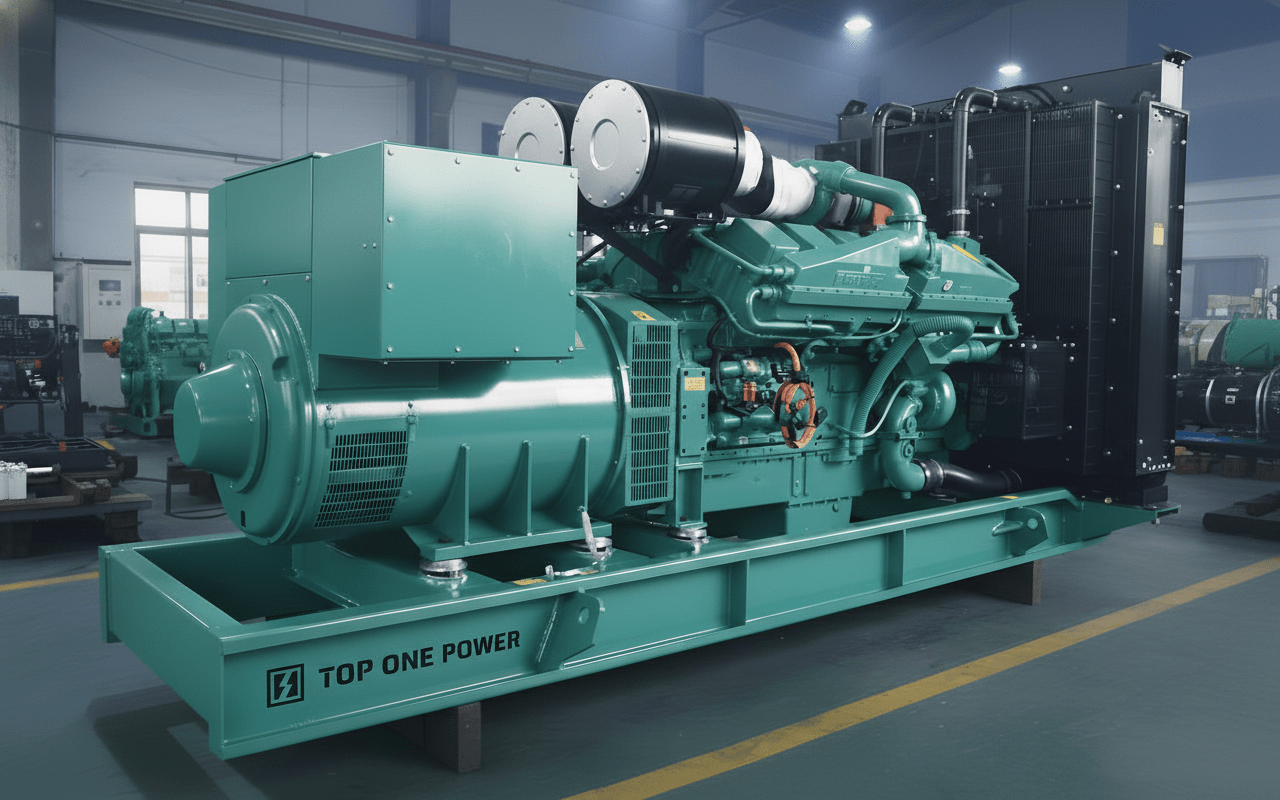

Choose High-Performance Cummins® Diesel Generators

We use globally renowned Cummins® generators, which are efficient, durable, and offer strong endurance, reducing the probability of issues like low diesel generator voltage or operational abnormalities, while comprehensively improving operational efficiency. Whether renting or purchasing generators, we provide complete pre-sales and after-sales services, including on-site surveys, transportation, installation and commissioning, as well as comprehensive maintenance and emergency support. This helps identify diesel generator failure causes, extend generator lifespan, and ensure stable power supply. Feel free to contact us— we will provide suitable generator products based on your needs and budget.